The Process

Recepies

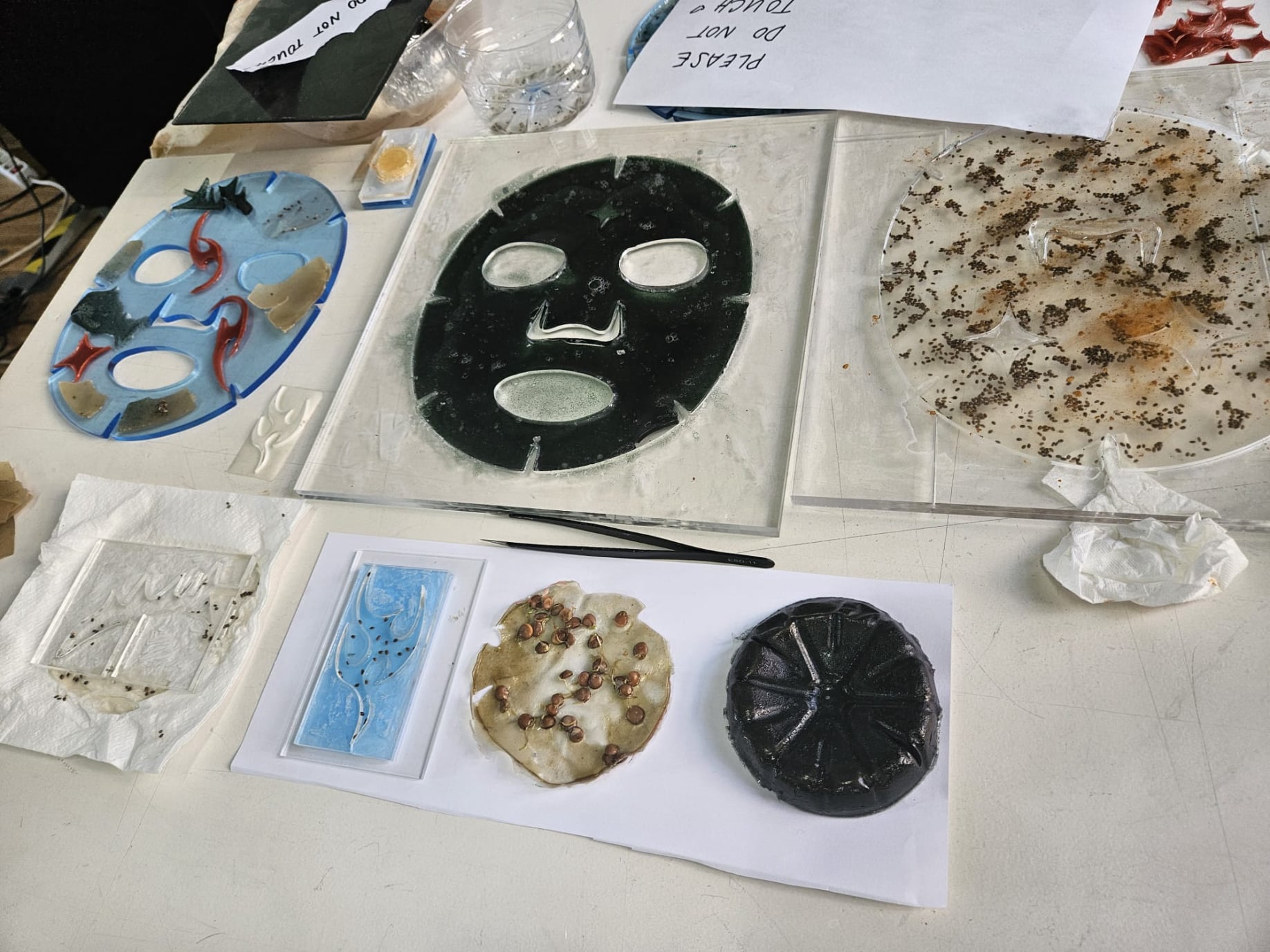

As we were searching for a sticky material, we decided to work with gelatin. We explored about four variations, including cornstarch, soap, spirulina, and carbon.

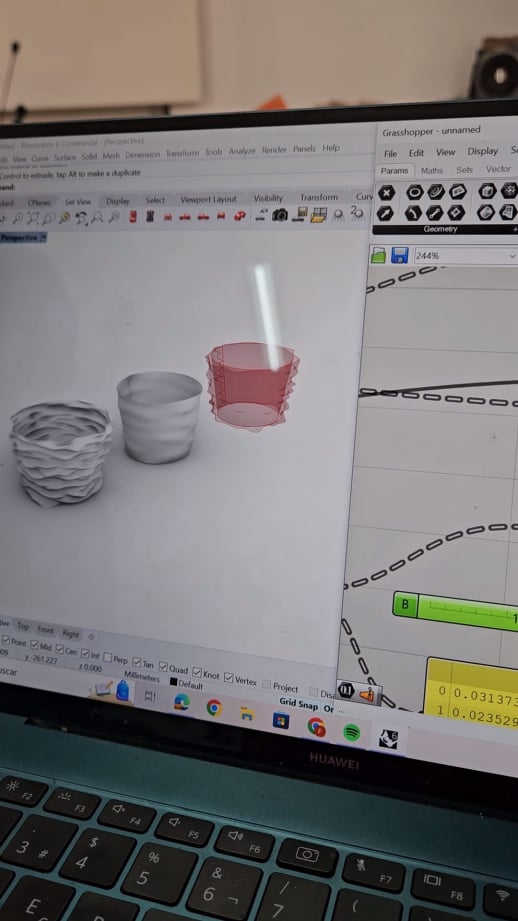

Shapes

To achieve our final results in terms of shape, we employed two different processes. In one method, we laser cut acrylic into the desired shapes and utilized them as molds. However, this approach resulted in excess material along the borders and a slight degree of shrinkage. In the second process, we prepared a sheet of biomaterials with acrylic and then laser cut it. This method led to a few more bubbles during the process, an uneven finish, and a thinner outcome compared to the molds.

Laser cutting the biomaterial sheet didn't yield the best results for the borders due to unevenness caused by calibration issues. This resulted in a slight overburn of the biomaterial along the edges. However, the imperfections were not very noticeable, and the final result was still very pleasing.

Other explorations

We also conducted additional exploration with other materials, such as agar agar, but encountered difficulties as it broke. Additionally, we experimented with germinated chia seeds and lentils, but they dried out afterwards.